- Our company

Our company

Customized filter and conveyor systems of the highest quality - sustainable and responsible

KÖBO ECO>PROCESS stands for customized filter and conveyor systemsthat are perfectly tailored to the needs of our customers and meet highest quality standards standards. Our expertise enables us, in close dialog with you individual solutions and develop optimal results to achieve. We strive to exceed your expectations and ensure that you are completely satisfied with our solutions.

Find out more about us

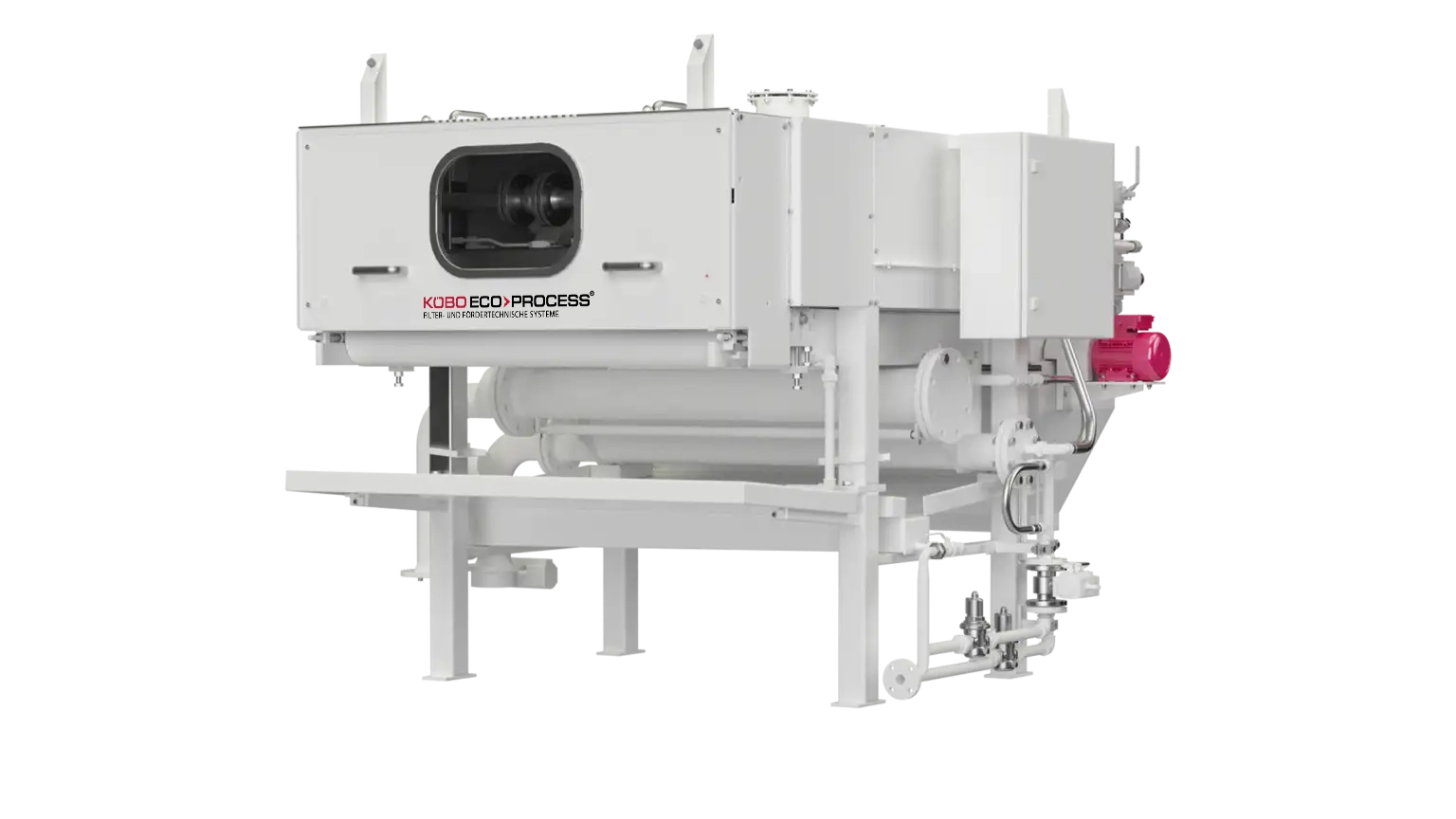

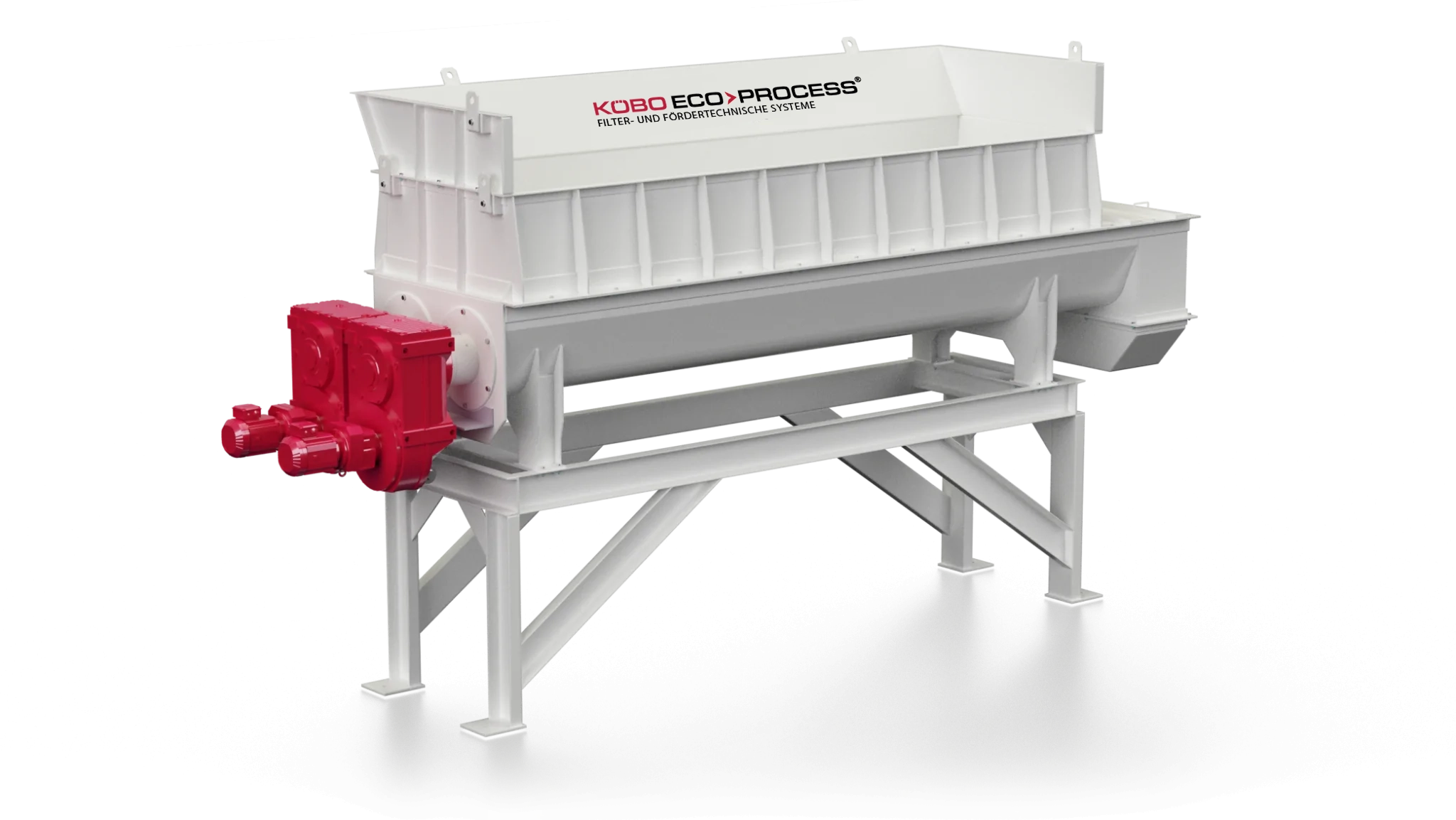

- Filter technology

Filter technology

Tailor-made filter solutions for a wide range of industries and applications

Discover filter solutions that are precisely tailored to your requirements.

KÖBO ECO>PROCESS presents imaginative filter solutions that have been specially developed for cleaning cooling lubricants, gear oil and washing water. Our filter technology not only offers maximum efficiency, but also state-of-the-art technical innovation and economic benefits.

KÖBO ECO>PROCESS focuses on customer-specific solutions to meet the individual requirements of our customers.Our products from the filter technology sector

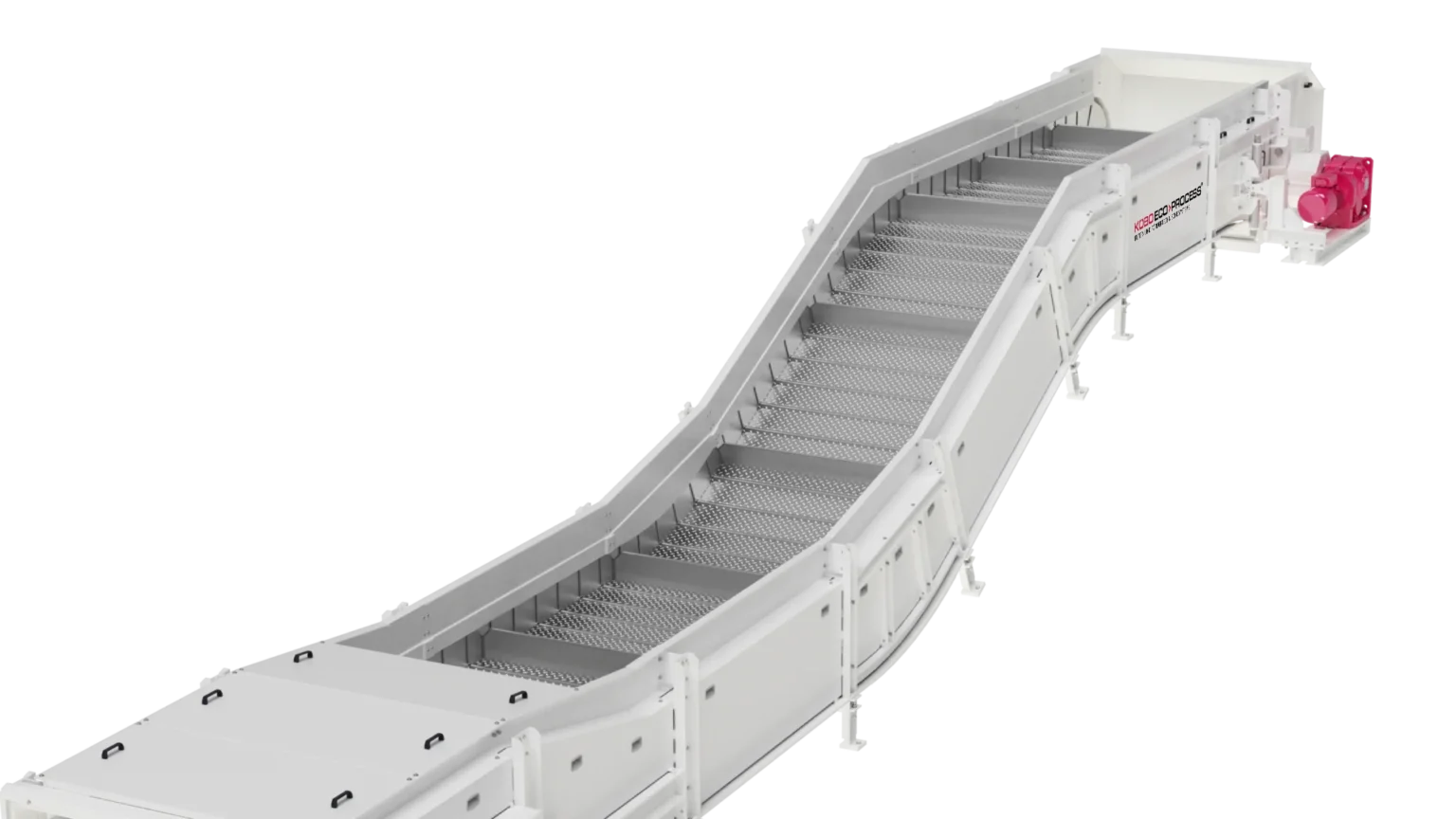

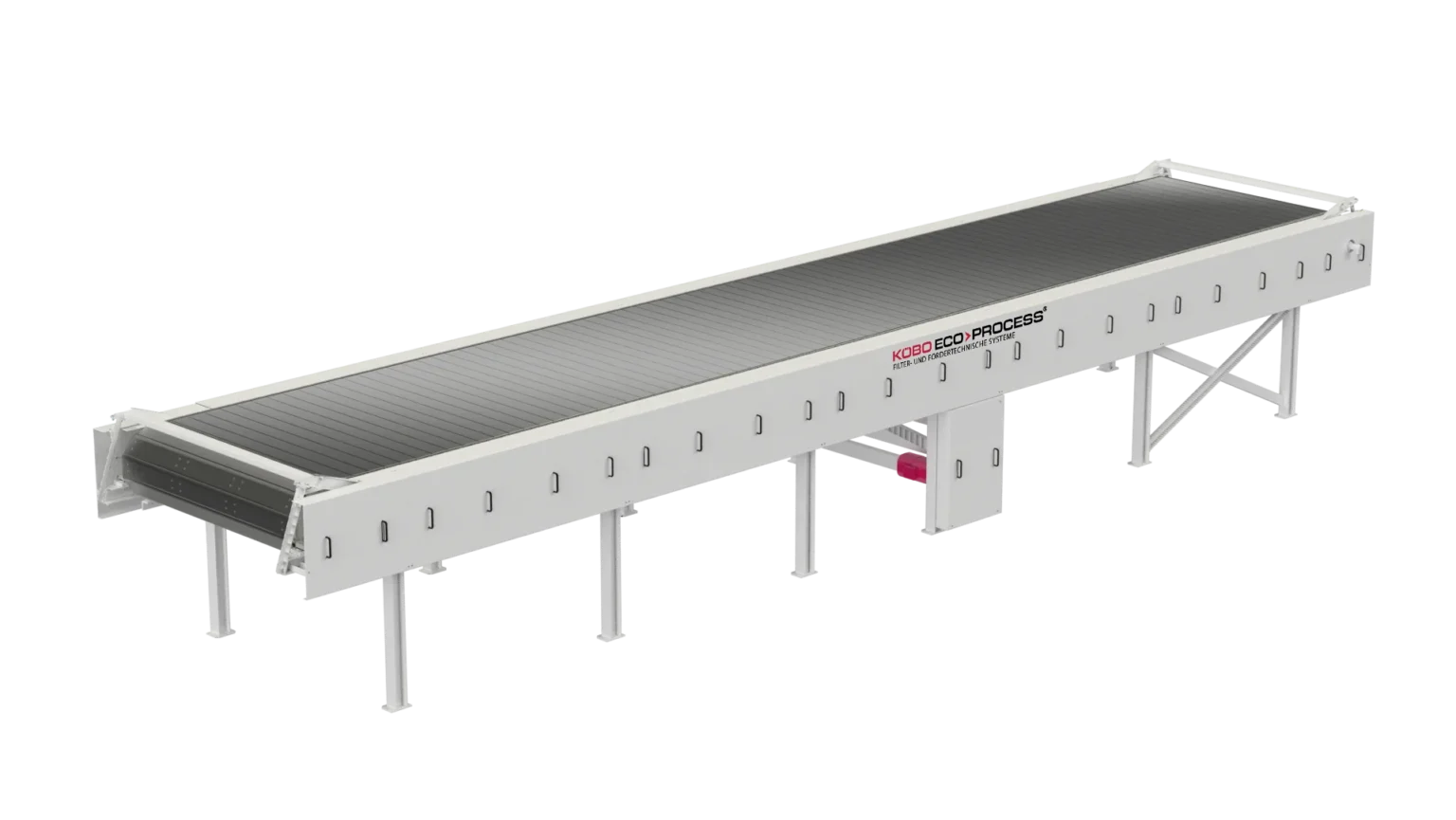

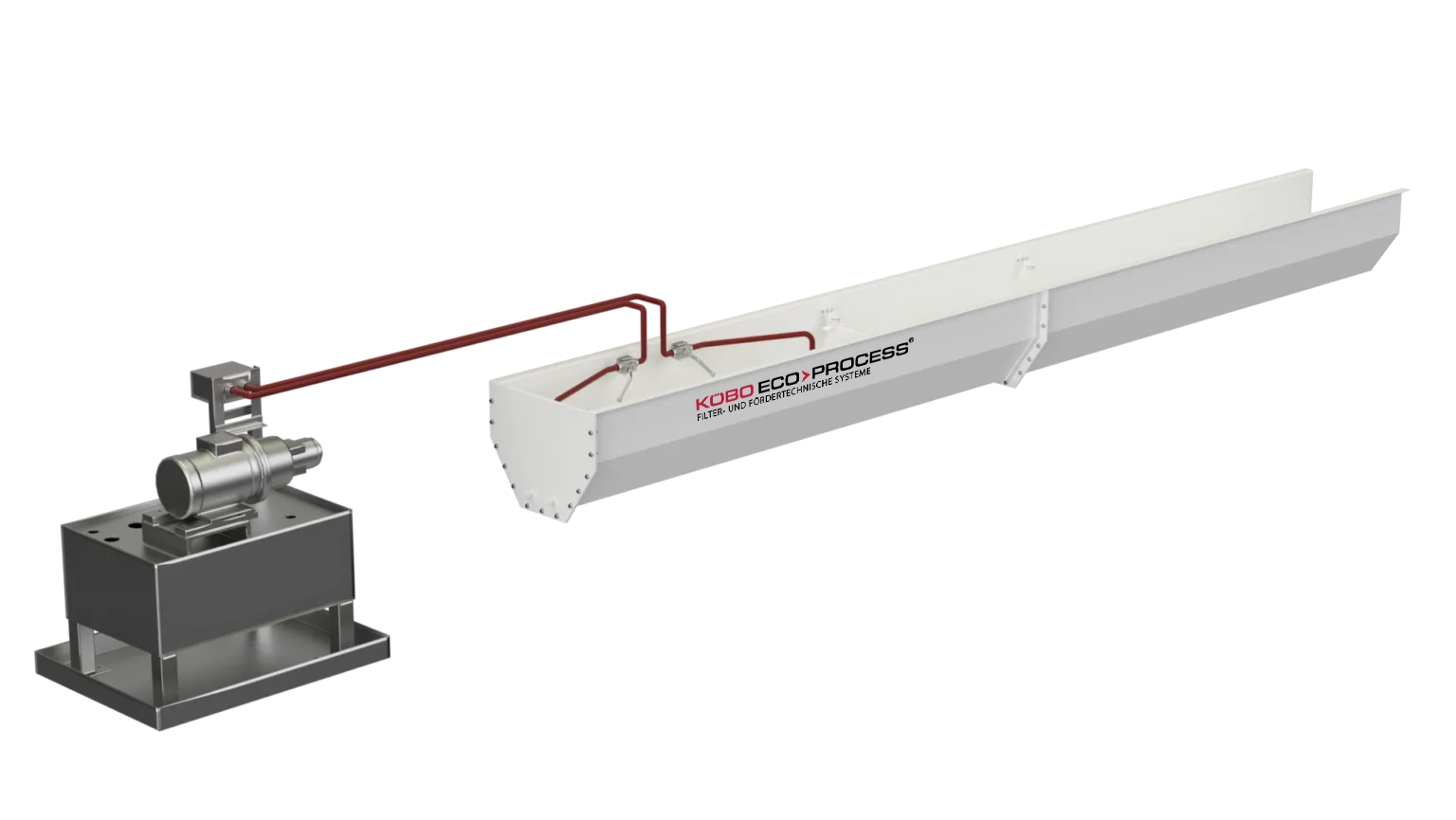

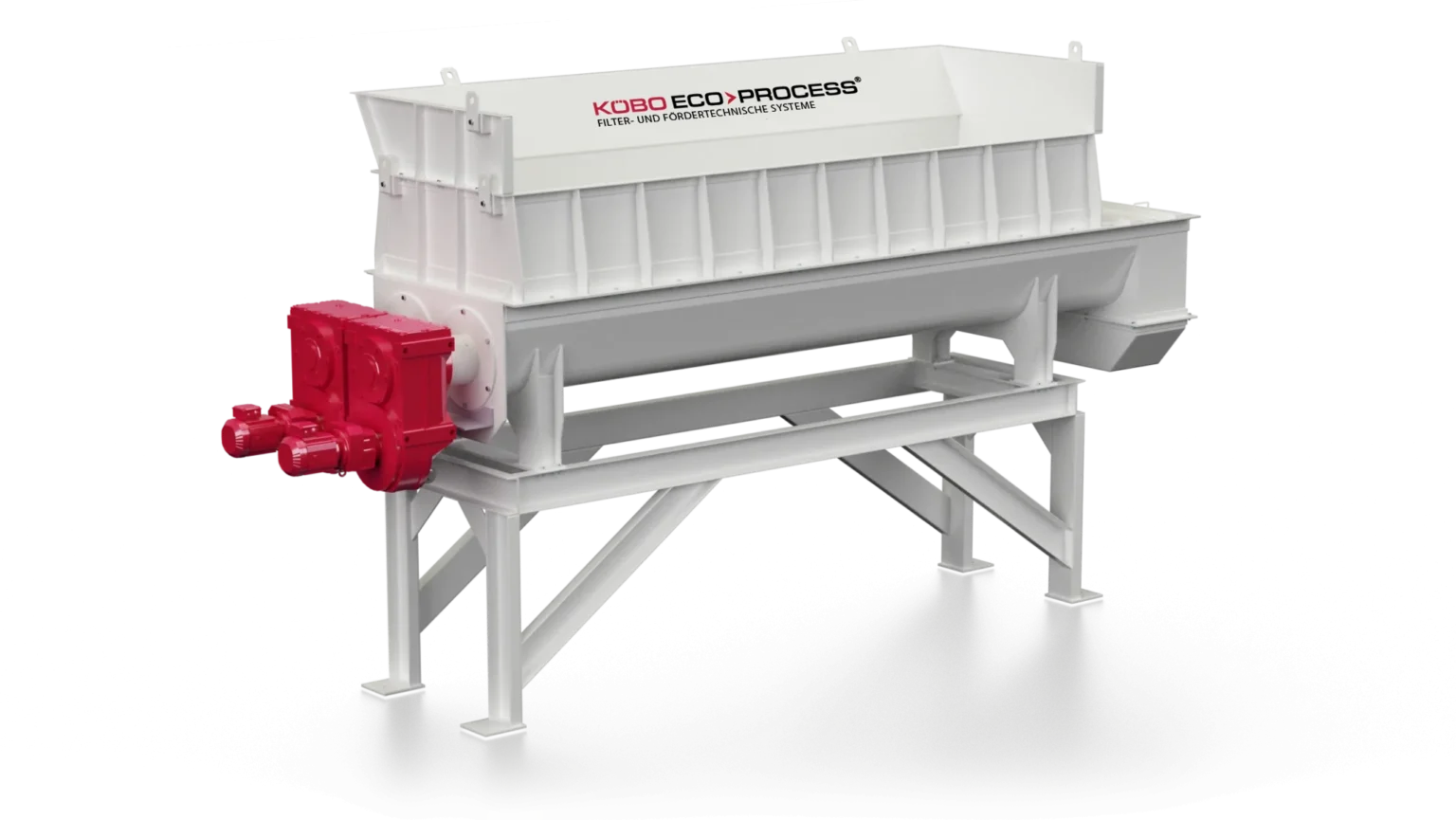

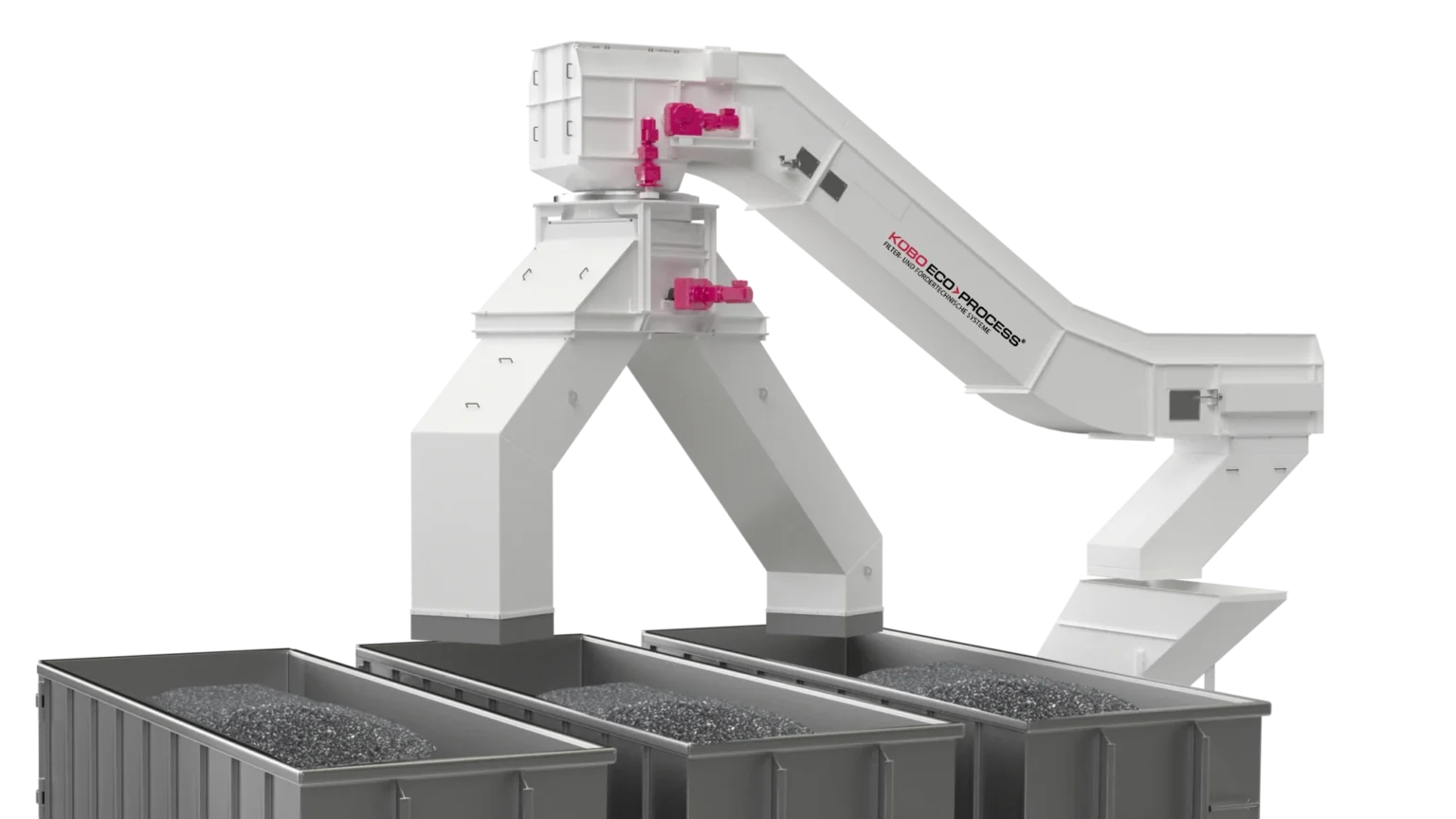

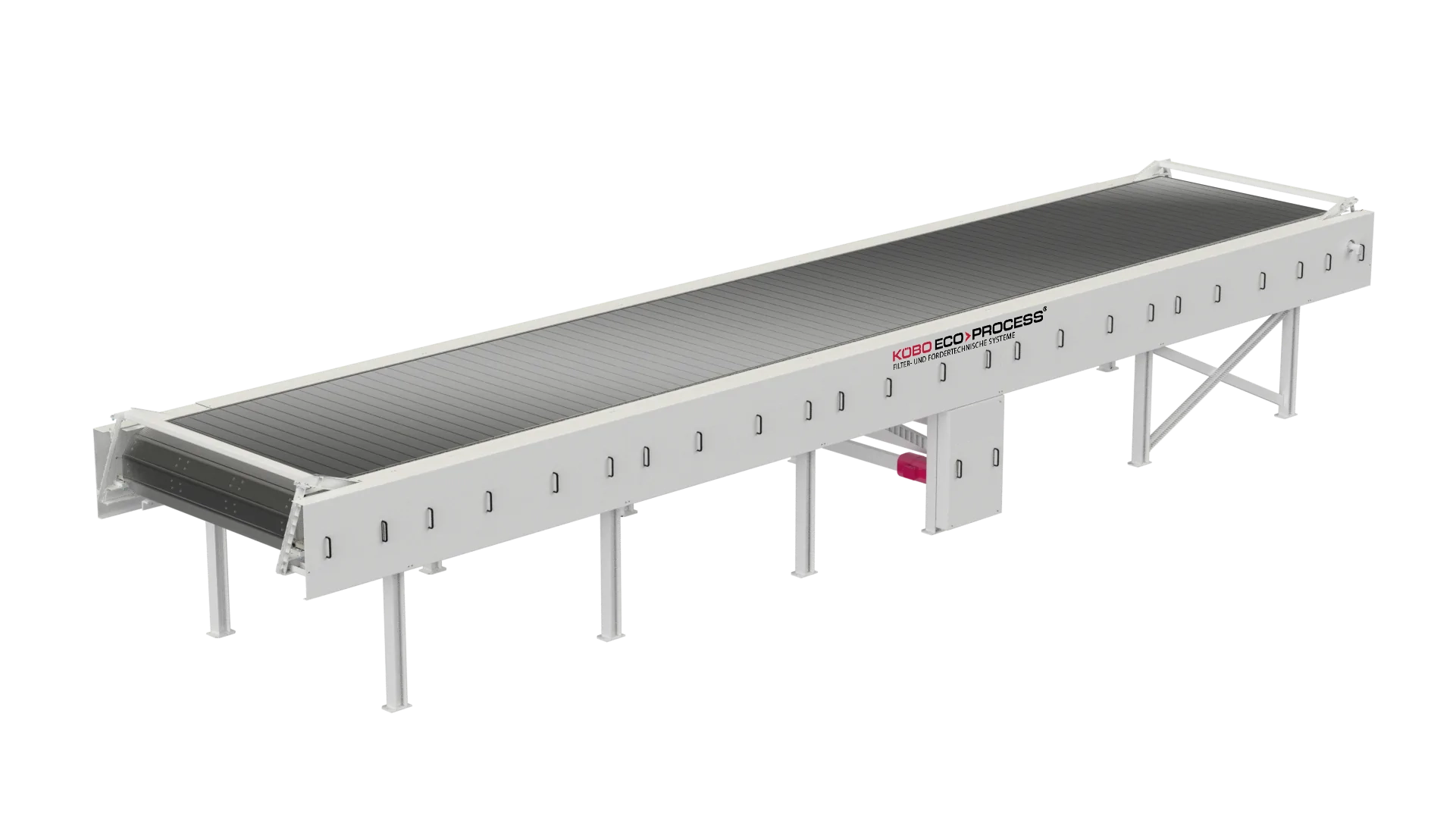

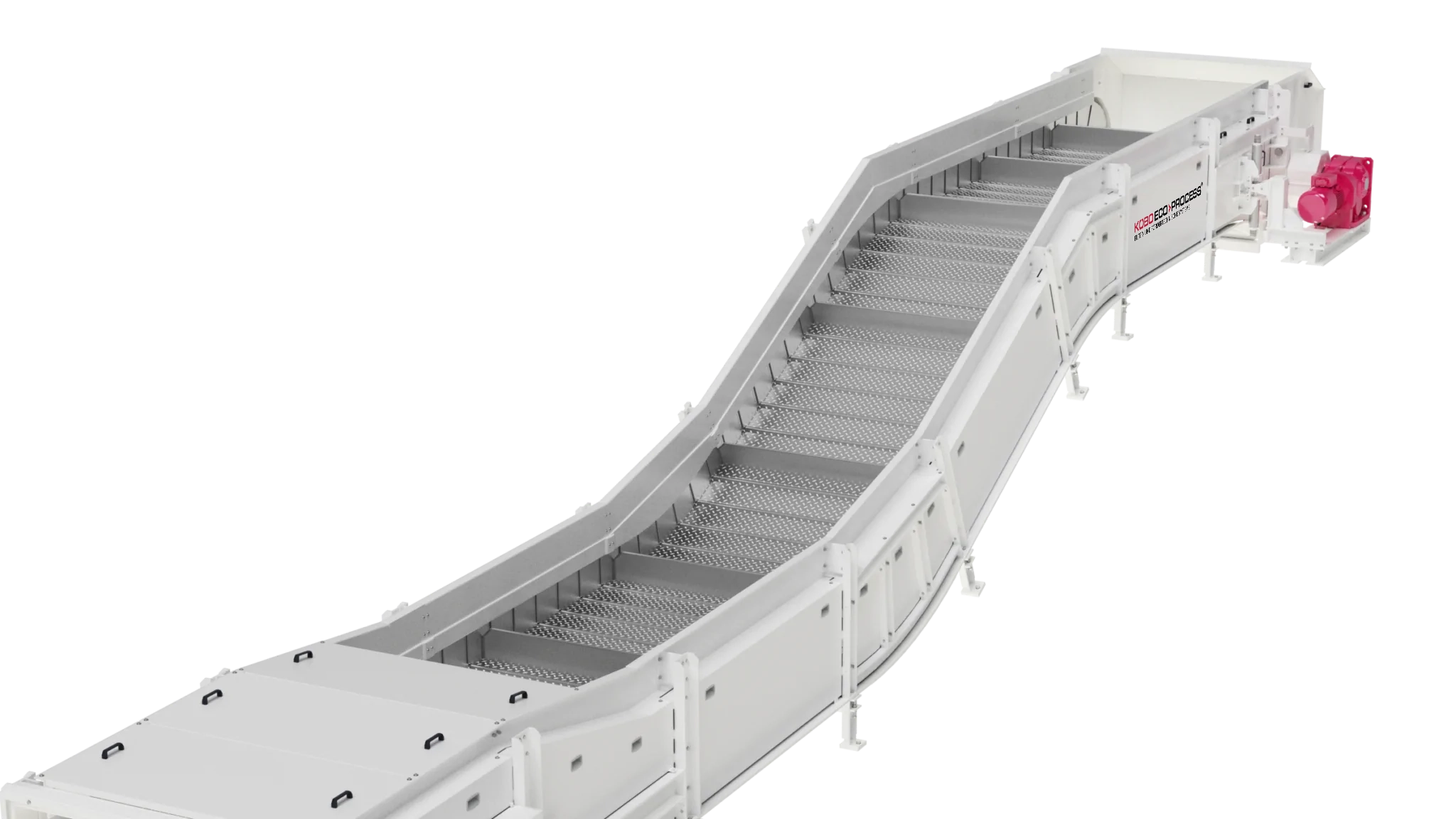

- Conveyor technology

Conveyor technology

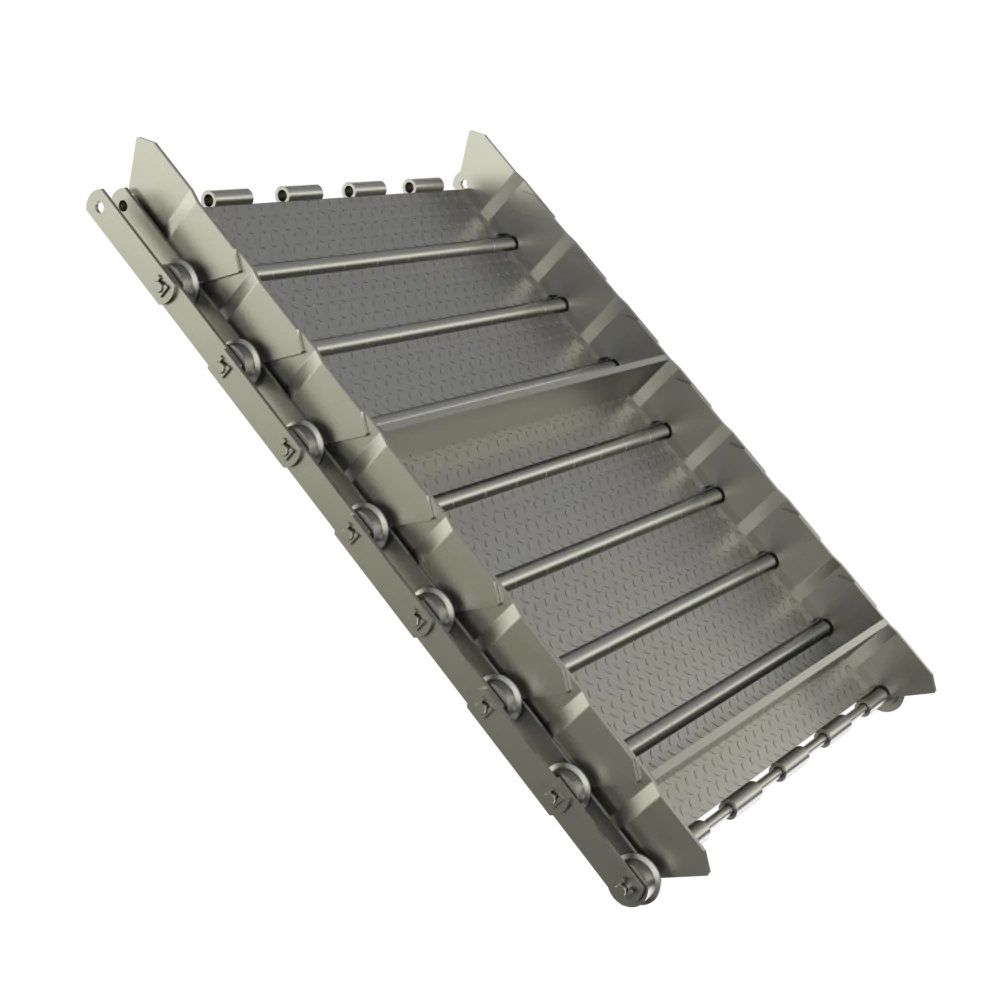

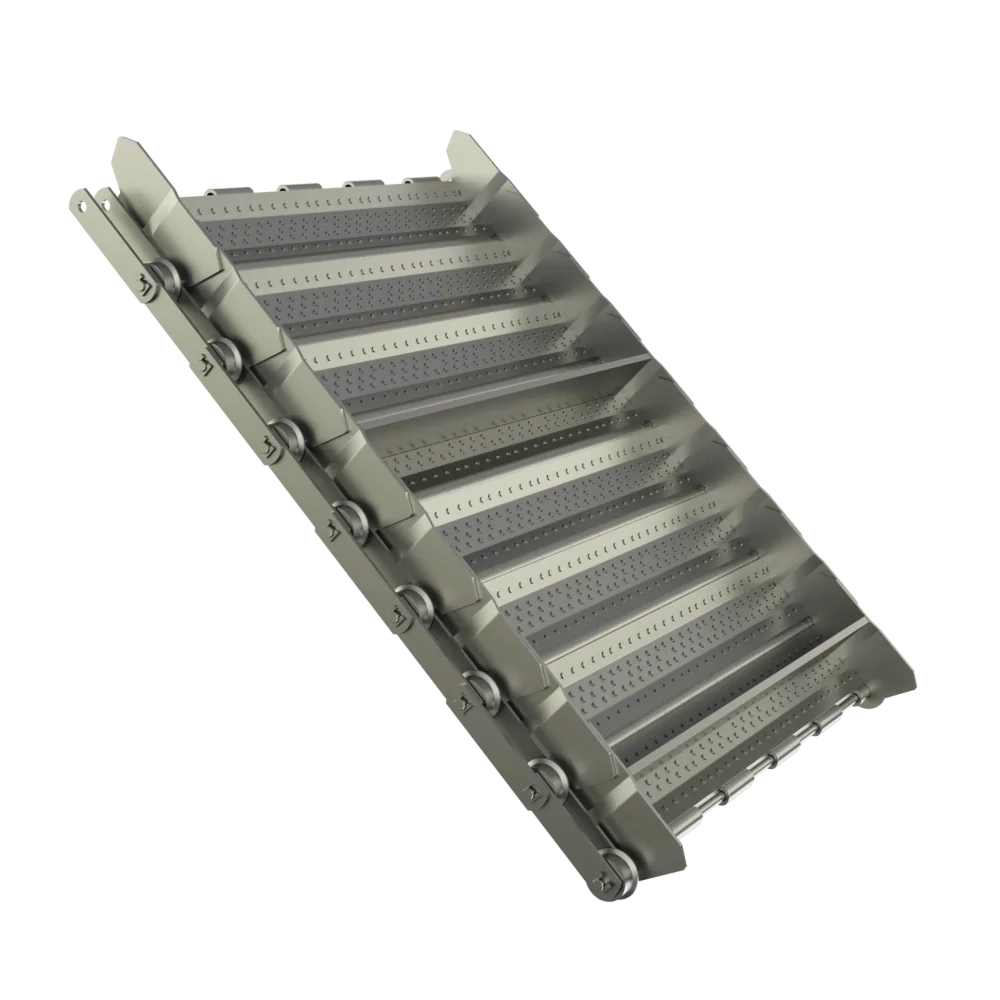

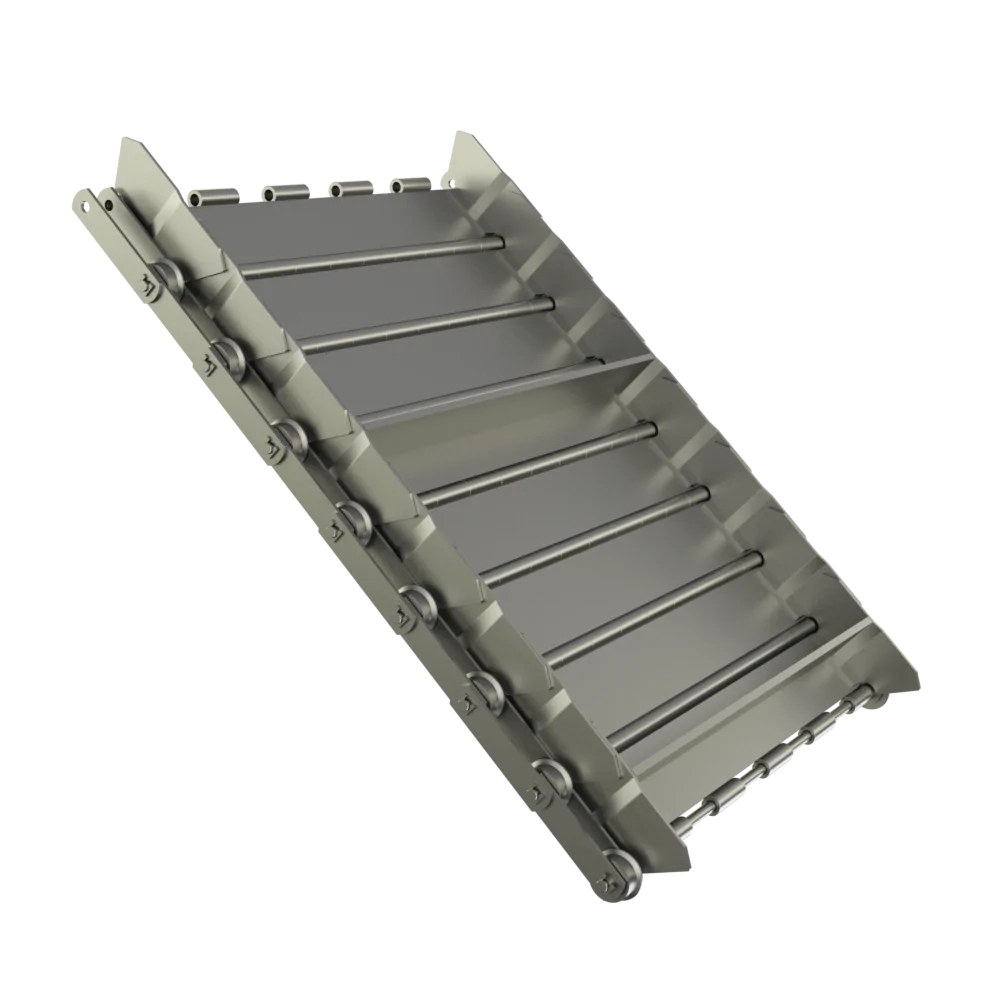

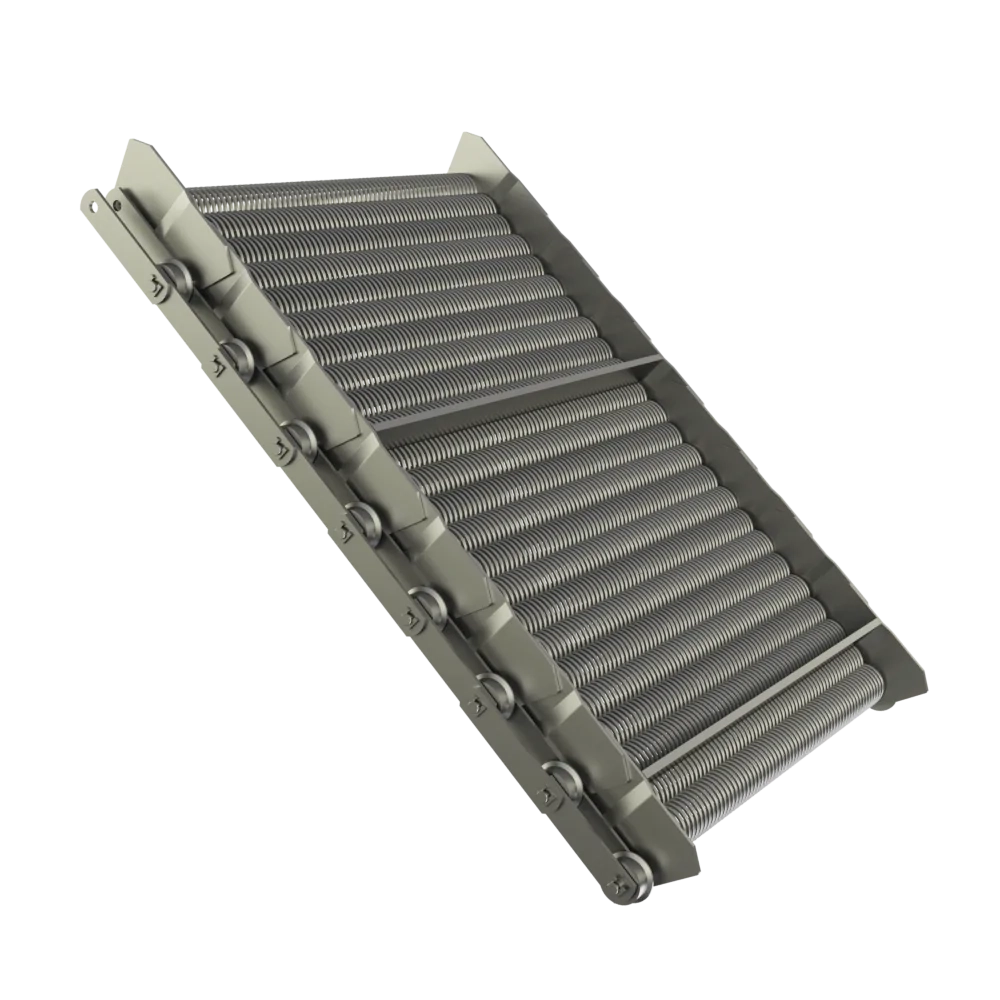

The right conveyor solutions for every industry and application

Our pioneering conveyor technology solutions are based on decades of experience in a wide range of industries and applications in mechanical and plant engineering. The conveyor technology of the KÖBO ECO>PROCESS has been specially developed for the reliable transportation of chips, bulk materials, scrap and heavy components.

Our conveyor technology is not only characterized by its outstanding performance, but also offers advanced technologies and economic optimization.

Our products from the conveyor technology sector

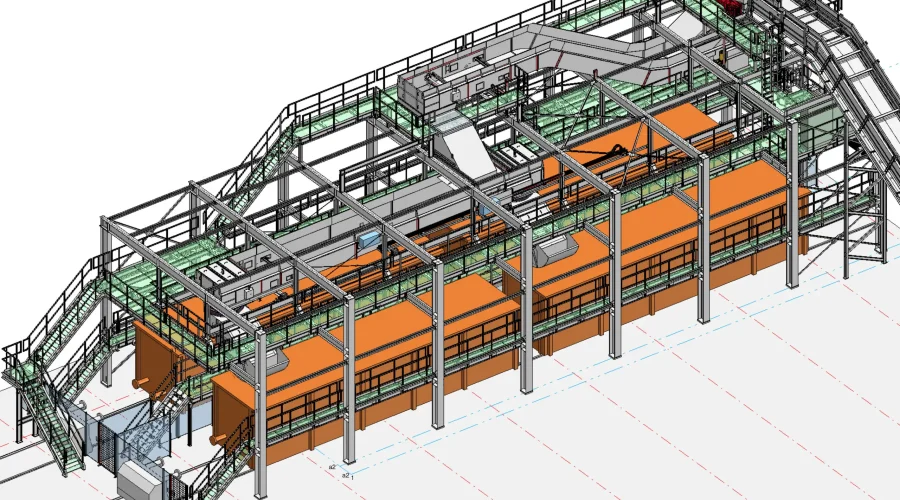

- Pipeline Construction

- Plant Construction

- Service

- Our company

Our company

Customized filter and conveyor systems of the highest quality - sustainable and responsible

KÖBO ECO>PROCESS stands for customized filter and conveyor systemsthat are perfectly tailored to the needs of our customers and meet highest quality standards standards. Our expertise enables us, in close dialog with you individual solutions and develop optimal results to achieve. We strive to exceed your expectations and ensure that you are completely satisfied with our solutions.

Find out more about us

- Filter technology

Filter technology

Tailor-made filter solutions for a wide range of industries and applications

Discover filter solutions that are precisely tailored to your requirements.

KÖBO ECO>PROCESS presents imaginative filter solutions that have been specially developed for cleaning cooling lubricants, gear oil and washing water. Our filter technology not only offers maximum efficiency, but also state-of-the-art technical innovation and economic benefits.

KÖBO ECO>PROCESS focuses on customer-specific solutions to meet the individual requirements of our customers.Our products from the filter technology sector

- Conveyor technology

Conveyor technology

The right conveyor solutions for every industry and application

Our pioneering conveyor technology solutions are based on decades of experience in a wide range of industries and applications in mechanical and plant engineering. The conveyor technology of the KÖBO ECO>PROCESS has been specially developed for the reliable transportation of chips, bulk materials, scrap and heavy components.

Our conveyor technology is not only characterized by its outstanding performance, but also offers advanced technologies and economic optimization.

Our products from the conveyor technology sector

- Pipeline Construction

- Plant Construction

- Service